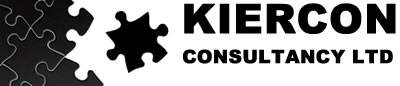

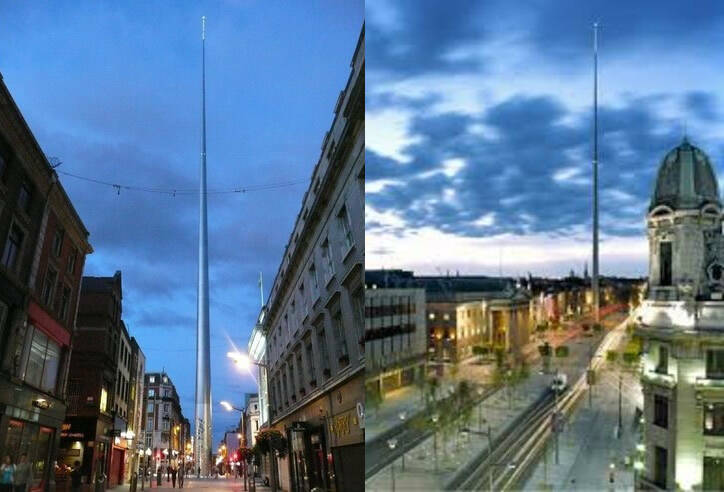

Spire of Dublin

The Spire of Dublin (aka Tur Solais, or Monument of Light) consists of eight hollow stainless steel cone sections, the longest being 20m (66ft). It is an elongated cone of diameter 3m (9.8ft) at the base, narrowing to 15cm (5.9in) at the top. It features two tuned mass dampers to counteract sway from wind forces. The steel plate sections underwent shot peening and extensive hand polishing in the work shop to alter the quality of light reflected from it.

The pattern around the 10m (33ft) lower part of the Spire was created by making a 3D pattern model combining the core sample of the rock where the Spire stands and a DNA double helix. The pattern was applied by bead blasting through rubber stencil masks whose patterns were created by water jet cutting.

The design around and then digitally translated to a 2D image drawing supplied to the contractor and used by specialists for cutting the masking material.

A curved 40mm thick polished stainless steel plate created a number of forming problems including application of the pressure needed to bend it without marking the surface, and as it was a conical shape, every piece was a different size, as the diameter of reduced with height. The tolerance on the bending was ±1mm on the diameter. The straightness over the length had to be within 6mm of the exact centre line. Before the bending process, the whole area, and machine itself, had to be cleaned to ensure there was no carbon contamination of the stainless steel and other operations, such as grinding and welding, were stopped to reduce carbon particles floating in the air. This was precision engineering and fabrication at the highest level.

The structure is founded on reinforced concrete piles with a basement chamber approximately 8m diameter by 5m depth to accommodate electrical and drainage equipment. Piles were installed using specialist-drilling rigs to socket them into the underlying rock. A 7m diameter circular base of bronze is connected to the concrete foundation flush with the surrounding paved area. The paving surround consists of Kilkenny black marble slabs which merge the base into the remainder of O’Connell Street’s paving pattern.

The Spire is prestressed to its concrete foundation with a 350kN tensile holding-down force in each of the 48 M60 bolts.

A stainless steel template was cast into the concrete to guarantee the alignment of the 48 holding down bolts. This was trial assembled with the first frustum of the Spire in the fabrication yard, prior to placing on site.

The erection of the Spire was akin to the structure: conceptually simple, but technically challenging. Conceptually, each frustum was delivered to site on the horizontal, raised to the vertical using two cranes (topped and tailed) and then lifted by one of Europe’s largest cranes onto the previous section, at which point the internal flange bolts were tightened. Among many technical challenges to be overcome were:

- The alignment of the 48 M60 holding down bolts to receive the 20t first section

- The levelling of the first section and subsequent grouting of the base plate to the concrete plinth

- The safe erection of each frustum, particularly as the height increased, and internal diameter decreased

- The temporary stability of the partially completed Spire prior to the final erection and releasing of the TMDs.

Internal access to the architectural and aviation lighting at the top of the Spire is restricted by the tapering diameter. A These items are, therefore, installed with a raise and lower system, so that they can be lowered to the base of the Spire for maintenance. The raise and lower system consists of a winch near the base of the Spire and a cable reeler at the top. In the event of the cable reeler at the top of the Spire fails to operate, external access is required. Provision has been made in the design and construction of the Spire for man access to the top, without the use of large capacity cranes. External access is gained via a rope system using a line of external anchor holes at 750mm centres up the Spire surface, which are capped off with a removable (threaded) cap. These caps are removable from inside initially but are then removed externally at the upper levels where the taper precludes internal removal. Access to the first 20m of the Spire is gained via cherry picker or mobile access platform. This provides access for general cleaning required for the stainless steel of the Spire. A collapsible access platform can be erected by the rope access team at the top of the Spire to provide a safe working platform.

At dusk, the base of the monument is lit and the top 10m (33ft) is illuminated through 11,884 holes through which light-emitting diodes shine.

A time capsule was placed and secured within the Spire Foundations containing a number of items to inform 23rd century Dubliners about life in the 21st century.